KP4000

Flocculating Agent

| Product Sheet | MSDS Sheet |

DESCRIPTION

KP4000 is a dry, natural organic polymer that has proven to very effectively flocculate and precipitate insoluble materials from water, pulp, and liquor streams. It is also used to enhance sludge filtration on rotary vacuum filters or leaf filters.

MIXING AND FEEDING

KP4000 is normally wetted with fresh water using a venturi type eductor. KP4000 is usually diluted to 0.1% to 1.0% by weight with water and allowed to hydrate for 4 hours or more before using. Unlike polyacrylamides, KP4000 hydrates best under a high shear mix condition. Enhanced activity can be achieved by further secondary dilution (e.g. 0.05 to 0.3%) before it contacts high solids pulp or solutions.

VISCOSITY

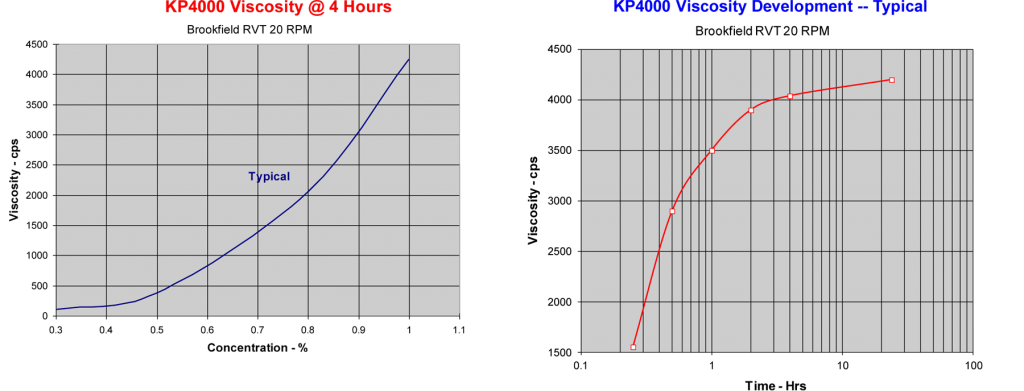

KP4000 hydrates, dissolves and develops viscosity over a period of time as indicated in Figure 1. Normally a period of 4 hours or more of aging time should be allowed to fully develop the polymer.

The viscosity of KP4000 solutions increase with concentration in an exponential manner. Planning of mixing and feed systems should take into account the viscosity characteristics of KP4000 that are illustrated in Figure 2.

FLOCCULATION

Guar gum’s long-chain polysaccharide structure with many exposed hydroxyl groups enables it to act as an inter-particle bridging flocculant for clay and other siliceous mineral particles. By partial and simultaneous adsorption onto more than one particle surface, a single molecular chain of the guar gum’s polysaccharide is able to form one or more interparticle bridges. The result of the formation of a network of these molecular bridges amongst many of the particles is the formation of flocs.

Particles that have a large negative electrical surface charge (zeta potential) may require a reduction of this charge in order to permit bridge formation to occur. This reduction is usually effected by the addition of trivalent positively charged ions of iron (Fe3+) or aluminum (Al3+) { provided by the addition of water solutions of “alum” (Al2(SO4)3б18H2O) or ferric chloride (FeCl3б6H2O) } or positively charged polymers such as Rantec RT CatFloc.

BENCH TESTING

Good planning starts with bench scale testing. Bench tests of KP4000 prior to plant use can be used to determine the optimum ranges of feed rates, addition locations and sequences.

Cylinder and/or jar studies are typically per-formed using a 0.1% by weight solution aged four hours then added to fresh liquor pulp. The best results may be achieved with KP4000 alone, or in conjunction with other synthetic polymers.

When used in conjunction with other polymers, the order of addition should be tested. In some systems the best results are achieved by separate, sequential feeds (adding and mixing the KP4000 first, followed by the synthetic), in other systems the best results are achieved when the KP4000 and the synthetic are mixed and fed together.

PRESERVED SOLUTION

KP4000 is a natural organic polymer that must be protected against spoilage. Good plant hygiene and periodic cleaning of mixing and storage tanks will reduce potential for spoilage. For severe applications in warm climates or problem areas KP4000-P can be supplied. KP4000-P contains biocides de-signed to prevent spoilage of polymer solutions. Rantec will also recommend effective biocides that may be added to the solution in-plant to prevent spoilage.

SAFETY

KP4000 is a natural organic polymer often used in food ingredients as well as industrial applications. It is non-polluting and non-toxic. It is totally biodegradable, so disposal problems are reduced. KP4000-P contains a biocide and should be handled accordingly.