Rantec G150™

GUAR GUM BASED BIOPOLYMER

| PDF Product Sheet | PDF MSDS Sheet |

DESCRIPTION

G150 is Rantec’s guar gum-based natural polymer (galacto-mannan) for biopolymer liquid shoring fluids (BLSF) and

drilling muds. Molecular weight is in the range of 1.5 to 2.0 million. G150 BLSF has been used extensively for geotechnical stabilization of extraction trenches during excavation and construction and well bores during drilling. G150 is biodegradable and can be broken down completely thus maintaining the permeability of those soils and producing formations. Rantec has more than 16 years of experience in supplying G150 for use in liquid shoring and drilling applications. As part of Rantec’s continued improvement program G150 in now easier to mix, less dusty and produces more viscosity per pound.

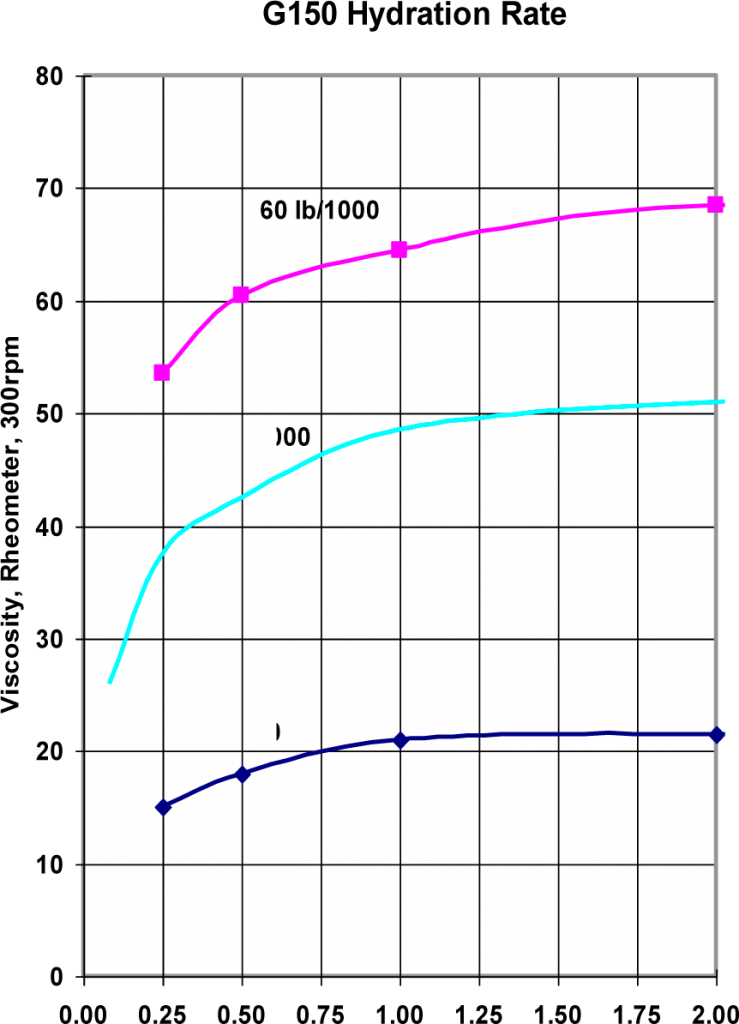

Figure 1: Viscosity with Concentration shows fresh water viscosity for a range of concentrations of Rantec G150

biopolymer.

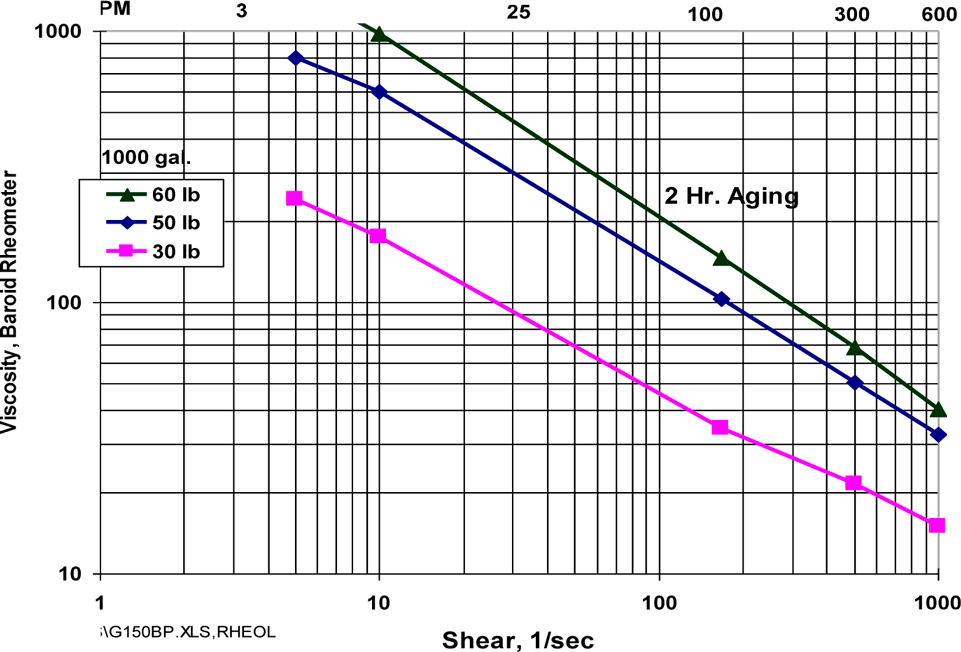

Figure 2: Rheology

Rantec G150 BLSF is a non-Newtonian “shear-thinning” fluid. At low shear rates a gel is apparent, while under

high shear, viscosity is very low. Figure 2: Rheology demonstrates these rheological characteristics of the fluid.

High viscosity in the gel state or low shear condition is important for prevention of soil or water movement, while

low viscosity is important under higher shear conditions such as mixing and pumping.

G150 fluids immediately recover original viscosity as soon as shear is relieved. High shear will not destroy the

G150 polymer molecule as can occur with many synthetic polymers.

YIELD AND MIXING

Typical design mix for G150 in difficult conditions would be:

| G150 | 50 to 70 lb/1000 gallons |

| Busan 1059WS | 1.2 to 2.0 lb/1000 gallons |

| Soda Ash | 5 to 8 lb/1000 gallons to maintain pH 10 |

| Lime | 1 to 3 lb/1000 gallons if required to maintain pH 1 |

Rantec G150 is designed to provide easy mixing and good yield of viscosity. G150 yields workable vis-cosity in about 1 hour and is fully yielded in about 4 hours. Figure 3: Viscosity Development demon-strates the development of viscosity through a period of 24 hours. In 1 hour G150 has yielded 90% of its viscosity. G150 responds well to high shear mixing. Additional shear will accelerate the rate of viscosity yield. Rantec will provide assistance in choosing equipment suited for good mixing of G150 fluid. Systems can be engineered for a wide range of capabilities from manual addition to fully automated systems.

IN USE CHARACTERISTICS

Typical Use Rate – 60 lb/1000 gallons (0.72% w/w)

Odor of Broken Slurry – Not noticeable under aerobic conditions. May become putrid under anaerobic conditions.

BOD of Broken Slurry – Typically approximately 1200 ppm.

Useful Life of Slurry – 3 to 10 days depending upon temperature, soil conditions and additives

Degradability – Approximately 10 to 12% insoluble residue after enzyme break

PACKAGING

Rantec G150 is available in packaging from 20 lb pails to 2000 lb super sacks. The most common packaging is 50 lb multi-wall paper bags. All packages are loaded on pallets and stretch wrapped to protect the product. For out-side storage pallet covers can be provided on request.

SAFETY

G150 is a natural organic polymer often used in food ingredients as well as industrial applications. It is non-polluting and non-toxic. It is totally biodegradable, so disposal problems are reduced. Preservative can be used for long term applications. G150 is non-mineral, therefore, it does not contaminate trenches, surroundings or as-says.